Liycy Cable applies in Mexico's oil and gas industry

As a leading cable supplier committed to meeting the diverse needs of industries, we have conducted a comprehensive study on the cable applications within Mexico's dynamic oil and gas industry. We will present a case study on applying LIYCY control and instrumentation cables in the Mexican oil and gas sector. This explores the specific challenges faced by the industry and the instrumental role these cables play in ensuring seamless control and communication within critical operations.

Challenges in Mexico's Oil and Gas Industry:

Challenges in Mexico's Oil and Gas Industry:Mexico's oil and gas industry is characterized by demanding conditions, presenting unique challenges for electrical systems. Key challenges include:

Harsh Environments: Exploration and extraction activities often occur in challenging environments, including offshore platforms and remote onshore locations with extreme temperatures and corrosive conditions.

Safety and Regulation: The industry is subject to stringent safety regulations, necessitating electrical systems that adhere to international standards to ensure the well-being of personnel and the environment.

Reliability and Continuity: Uninterrupted power supply is critical for drilling, pumping, and refining processes. Any disruption can lead to costly downtime and compromise safety.

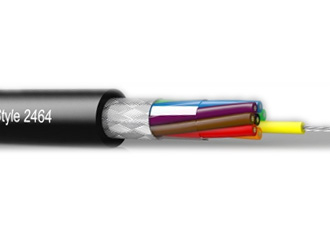

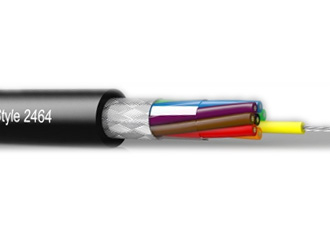

Application of LIYCY Control and Instrumentation Cables:LIYCY cables are specifically designed for control and instrumentation applications, making them an ideal choice for the complex requirements of the oil and gas industry. Here are some key applications:

Control Panels: LIYCY cables are used in control panels to transmit control signals between various devices and systems, ensuring precise control over equipment and processes.

Instrumentation Systems: These cables play a vital role in connecting sensors, transmitters, and other instrumentation devices, facilitating the accurate measurement and monitoring of parameters such as pressure, temperature, and flow.

Communication Networks: In a digitalized oil and gas environment, LIYCY cables provide the backbone for communication networks, enabling seamless data transfer between different control system components.

Automation Systems: LIYCY cables are integral to the automation of processes, allowing for the efficient and reliable control of machinery and equipment involved in oil and gas operations.

Benefits of LIYCY Cables in the Oil and Gas Industry:

Benefits of LIYCY Cables in the Oil and Gas Industry:Electromagnetic Interference (EMI) Shielding: LIYCY cables are designed with shielding to protect against electromagnetic interference, ensuring the accuracy and reliability of control signals in environments with high levels of electrical noise.

Flexibility: The flexibility of LIYCY cables makes them suitable for installations in confined spaces and complex layouts, common in oil and gas facilities.

Data Transmission Integrity: These cables provide high-quality data transmission, critical for the integrity of control and instrumentation systems, reducing the risk of errors and improving overall efficiency.

Durable Construction: LIYCY cables are constructed with materials that resist harsh environmental conditions, ensuring longevity and reliability in challenging oil and gas environments.

Our LIYCY control and instrumentation cables play a pivotal role in the Mexican oil and gas industry by addressing the specific challenges related to precision control, harsh environments, and data integrity. Their application in control panels, instrumentation systems, communication networks, and automation systems contributes to the efficiency, safety, and reliability of operations in this critical sector.

For more information on LIYCY cables or to discuss specific requirements for your oil and gas applications, please contact us.

Get a free quote by E-mail:info@cable-uni.com We are dedicated to providing tailored solutions to support the evolving needs of Mexico's dynamic oil and gas industry.